Participating in challenging projects that support clean energy development in Canada can be one of the most attractive aspects of working in the hydrogen industry.

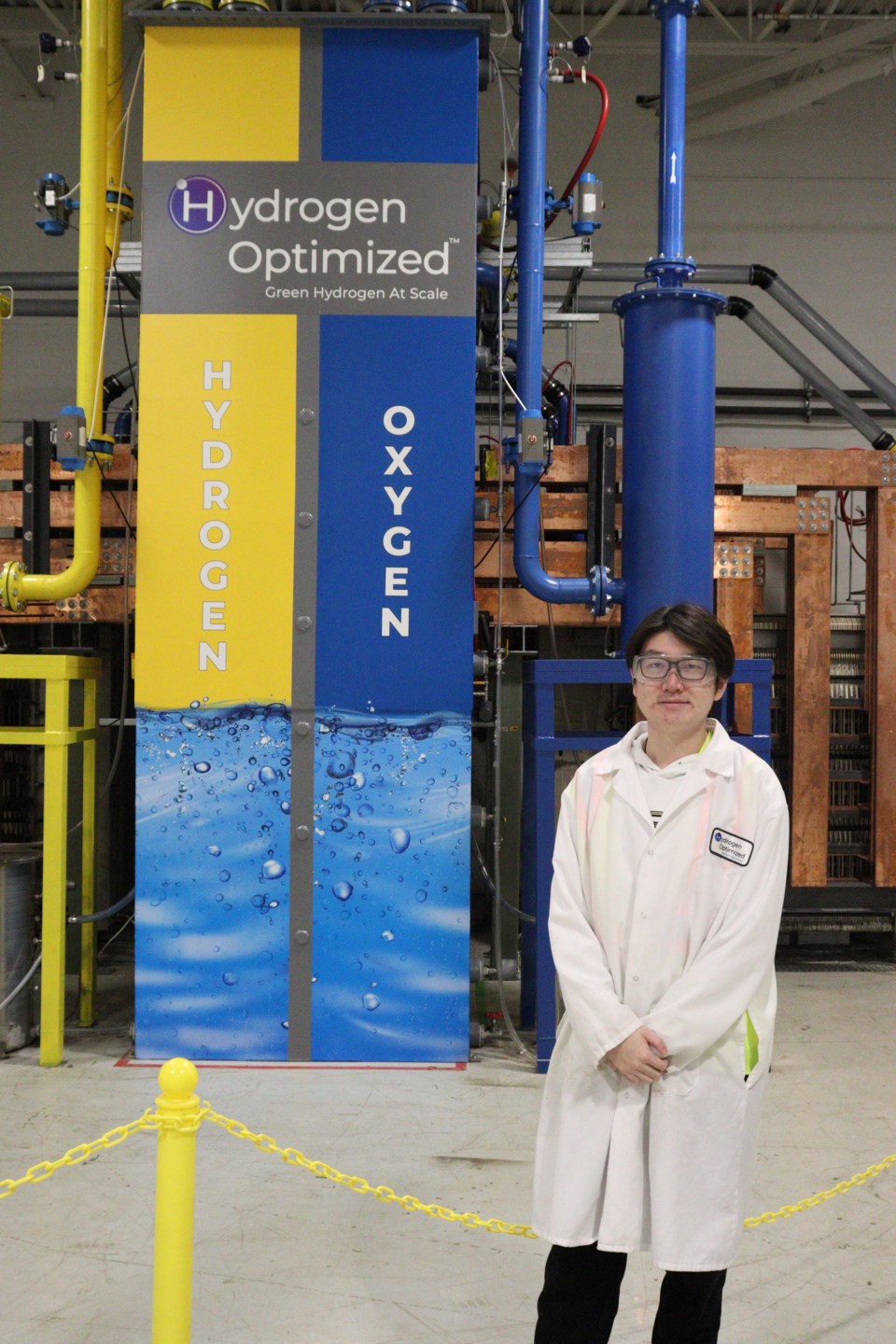

“We seek to overcome some leading-edge challenges in technological development,” says Shawn Peng, a materials engineering intern at Hydrogen Optimized, a manufacturer of electrolyzers, which are devices that split water into oxygen and hydrogen.

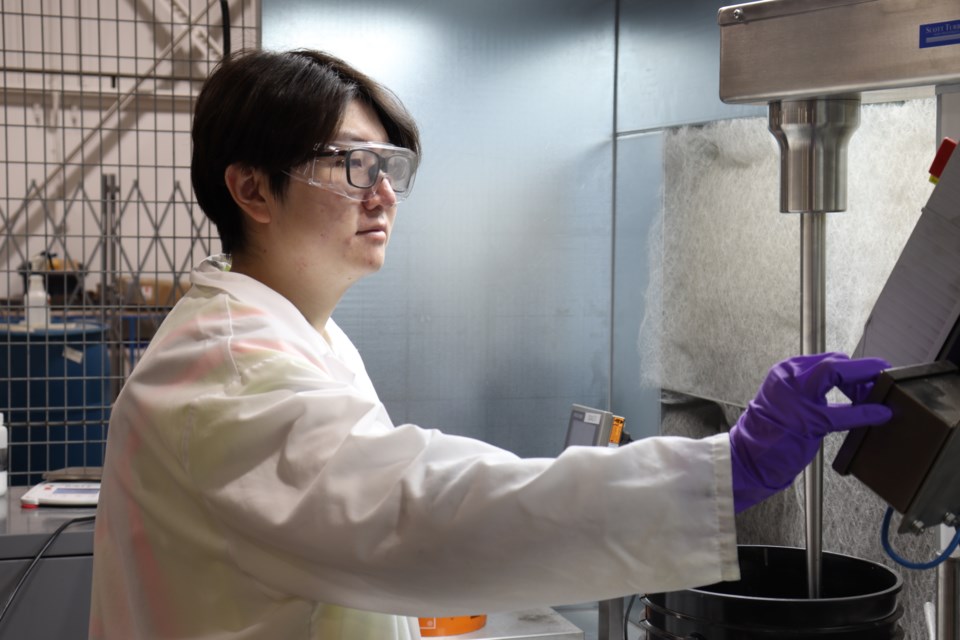

Peng’s role includes research and development of catalysts, which facilitate electro-chemical processes in electrolyzers.

“Chemical experiments are like playing with a black box. By changing the input to the black box, you will get different results," Peng adds.

However, figuring out what happened inside the black box is really challenging and requires a lot of research, he says.

“I’m excited to join those projects and look deeply at those questions at the materials level," Peng says.

Peng tells BarrieToday that most of the research and development projects happen in the lab, which is equipped with many cutting-edge instruments.

“In my projects, all the viscosity measurements are done there. The lab team is incredible. They help me a lot with my project," he says.

One of Peng’s projects is to investigate how to recycle some materials used during the production of electrodes.

“At the early stages of the project, my tasks focus on collecting those materials and filtering out elements of interest," he says.

The project involves separating the materials by their distinguishing properties, such as size, density and electromagnetism.

Next, Peng focuses on designing a series of experiments to produce catalysts with the desired properties, using recycled materials.

With a large-scale manufacturing plant in Owen Sound, Hydrogen Optimized offers several one-year co-op positions for university students on an annual basis.

“This is attractive for third-year students like me who are searching for opportunities to gain some experience," Peng says. "Many co-op students return as full-time employees after they graduate.”

Some research, testing and other activities are conducted at Key DH Technologies (KEY), the parent company of Hydrogen Optimized, which is based in Collingwood.

Peng says that during his co-op he had opportunities to operate machines under supervision.

“The training period for me was roughly two months. I have a mentor to teach me how to operate equipment used in the laboratory and on the production line,” he adds. “Most importantly, we have health and safety training for handling hazardous tools and chemicals.”

Besides knowledge of materials processing, Peng says some knowledge of fluid dynamics and thermodynamics is an advantage for the position of materials engineering intern.

“I think the most important skill is design of experiments," he adds. "For example, how to control the variables and analyze the results.”

While Canada looks to green hydrogen as part of its plan to decarbonize the economy, Peng says there are so many professions that are critical to developing electrolysers.

“Building electrolysers requires the co-operation of professions across multiple fields," he adds.

As an example, he explained that electrical and mechanical engineers at Hydrogen Optimized are responsible for designing a system to connect all the electrolyser cells together and a system that controls the electric current provided to the cell.

“Also, we need people engaged in software to develop an operating system for the electrolyser," Peng says.

Despite the increasing interest in lithium batteries as energy storage, Peng says both batteries and hydrogen will likely co-exist in a decarbonized future.

“Lithium-ion batteries currently dominate the small-volume energy storage markets for electric vehicles and electronic devices, but green hydrogen fits the need for large-scale industrial processes, such as steel production and chemical production," he says.

One advantage of green hydrogen over lithium-ion batteries is green hydrogen has less environmental impact than lithium-ion batteries, Peng says.

“Green hydrogen is produced by splitting water using renewable electricity with close to zero greenhouse gas emissions, while producing lithium-ion batteries requires a large energy consumption and carbon emission.”

The provincial government has also taken notice of advancements in hydrogen technologies. The province announced last week it was investing $5.9 million in nine new projects that will integrate hydrogen into the province’s electricity grid.

This funding is through the Hydrogen Innovation Fund, which supports projects that "pave the way for the production of reliable, affordable and clean electricity from hydrogen to help power the province’s growth."

Those projects include locations in Halton Hills, Cochrane, Goderich, Toronto and Hamilton. Capital Power is also receiving $206,000 to study the feasibility of blending hydrogen with natural gas (between five per cent to 15 per cent hydrogen) at their existing Brampton, Windsor and Newmarket generation facilities.

Barrie-Innisfil MPP Andrea Khanjin, who is also the minister of environment, conservation and parks, says it's "a plan that diversifies our energy supply to keep energy costs down while also reducing greenhouse gas emissions," according to a news release. “By investing in these innovative clean-energy projects, Ontario is supporting economic growth and securing environmental benefits for future generations."

As part of the province’s Low-Carbon Hydrogen Strategy, Ontario established the Hydrogen Innovation Fund in February 2023. It will invest $15 million over the next three years to kick-start and develop opportunities for hydrogen to be integrated into Ontario’s clean electricity system, including hydrogen electricity storage.

By 2050, the province says the hydrogen economy could create more than 100,000 jobs across the province, while reducing greenhouse gas (GHG) emissions by 50 mega-tonnes per year.

This reduction in emissions is expected to be equivalent to about a quarter of Ontario’s 2005 emissions or removing 15 million vehicles off the road.